By Michael Schmid of Renewable Nutrients

Conventional wastewater treatment facilities have evolved to become extremely proficient in the practice of sequestering nutrients, particularly phosphorus and nitrogen, present within their incoming municipal and industrial waste streams. Many facilities, and perhaps the case could be made to suggest “most” of the 16,000+ treatment plants in the United States, employ a form of chemical precipitation that serves to bind dissolved phosphorus to a metal salt or rare earth elements (e.g. – ferric chloride, alum or cerium chloride). This precipitations segregates the phosphorus such that it travels with the solids portion of the treatment process and thereby delivers to receiving waters a final liquid effluent that is low in phosphorus (or at least within a mandated tolerance for the nutrient).

The common practice of dosing an incoming waste stream with metal salts does have its disadvantages, however. In many cases, it can be rather costly just from a chemical consumption perspective, which is driven by the amount of daily incoming total phosphorus that needs to be isolated and removed from the liquid stream. The addition of metal salts also adds to the facility’s overall sludge content, creating more solids material that must be treated, digested, dewatered and ultimately disposed, and compounding the operational cost drivers that have to be controlled and managed. Finally, from an environmental standpoint, it simply cannot be beneficial long-term to landfill or even land apply biosolids that are artificially saturated with metals (and phosphorus), so beyond the daily cost of operations, there may very well prove to be a heavy cost to the environment.

Fortunately, many treatment facilities have recognized the operational and environmental costs associated with dosing metal salts and are employing alternatives. One emerging technology for managing incoming phosphorus, which has gained wide acceptance especially by progressive treatment plant operators, is bio-P. Here, phosphorus is captured and removed from the incoming liquid stream biologically by phosphorus accumulating organisms (PAOs). While bio-P can be very efficient at removing phosphorus and isolating it to the solids stream, the PAOs tend to release the nutrient from within their cell walls during and after anaerobic digestion. Unfortunately, this released phosphorus typically follows the liquid portion of the solid stream through dewatering, producing a high-P liquid side stream that is nearly always routed back to the plant’s head works, and must ultimately be re-treated again and again by the bio-P process. This side stream is commonly referred to as a “recycle stream,” and in many cases can exhibit phosphorus levels as high as or even exceeding 500ppm. Recycling this phosphorus-laden stream serves to limit the capacity and effectiveness of any bio-P process, yet it also yields a single, concentrated point or “reserve” from which phosphorus can be mined, recovered, and even re-used beneficially.

While academics and scientists have studied, debated, and preached about nutrient (and specifically phosphorus) recovery from waste streams for many years, putting the concept to practice is a relatively recent phenomenon. There are several new technologies on the market today that can assist a treatment facility in removing and recovering phosphorus from its waste streams, but one emerging technology that has proved particularly effective at recovering phosphorus from side streams or recycle flows is Quick Wash® – a concept originally developed by the USDA and commercialized by Renewable Nutrients.

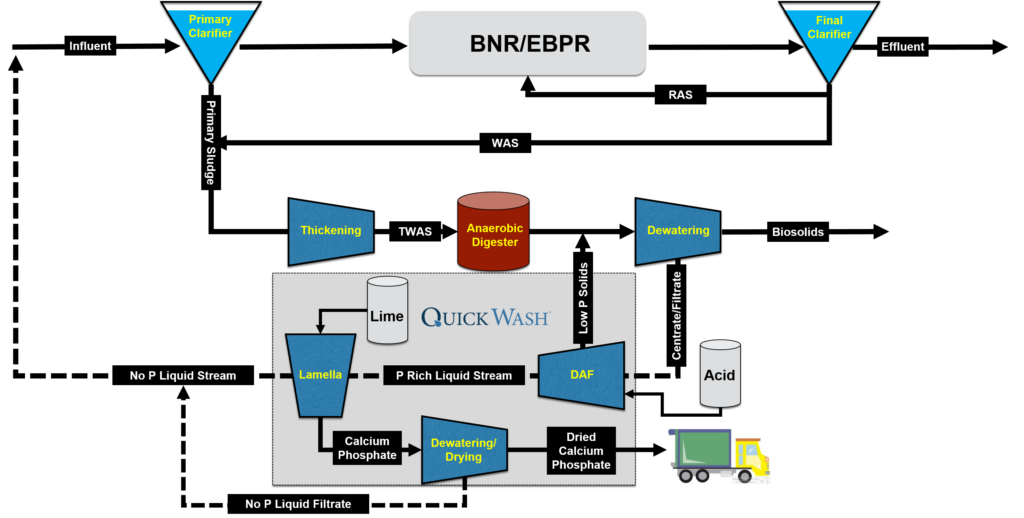

Quick Wash is versatile enough that it can recover phosphorus from both liquid and solid streams, but given a bio-P operation (also sometimes referred to as Enhanced Biological Phosphorus Removal – EBPR), one area in particular where it can be effectively deployed is downstream of dewatering to treat the liquid side stream (or recycle stream). In the illustration above, the Quick Wash system receives the recycle flow and extracts nearly all of the phosphorus that is not already in solution. The system then precipitates out the phosphorus by introducing lime and forming calcium phosphate. The calcium phosphate is filtered using a liquid/solid separation apparatus and can be used beneficially as a phosphate fertilizer, an animal feed additive, or as a supply of raw material where calcium and phosphorus are required. The final liquid effluent from the Quick Wash system is routed back to the facility head works as a clean, very low-P or even no-P stream. So Quick Wash not only recovers phosphorus and produces a valuable byproduct, but it eliminates the recycle flow of phosphorus and yields greater capacity and efficiency in a bio-P operation. This increased capacity gives a facility the flexibility to increase its incoming waste stream flow without the addition of major infrastructure upgrades.

Progressive wastewater treatment facilities that operate bio-P combined with anaerobic digestion are producing an untapped, yet readily available phosphorus reserve in the form of phosphorus-rich recycle streams. Recycling released phosphorus from the solid stream back into the liquid stream only serves to add to a facility’s daily phosphorus load and create a scenario in which its bio-P operation is unable to operate at its intended capacity. The phosphorus-rich recycle streams of such facilities present an opportunity for technologies not only to extract and recover phosphorus and re-purpose it for beneficial re-use, but also to eliminate the constant recycling and re-treating of phosphorus within a treatment plant. Given a finite or limited worldwide phosphate rock supply, and the need for phosphorus as a life-sustaining nutrient important to preserving global food security, it only makes sense to “tap” the phosphorus reserve created in treatment plant recycle streams. Thanks to technologies, such as Quick Wash, phosphorus recovery may soon be standard operating procedure and wastewater treatment plants may very well be able to truly own and live-out the moniker “Water Resource Recovery Facility.”

Opinions expressed here do not necessarily reflect those of the Sustainable Phosphorus Alliance.

About Renewable Nutrients

Renewable Nutrients is a private, North Carolina-based company that turns waste into sustainable and profitable resources. Through its patented Quick Wash® system, Renewable Nutrients enables waste treatment facilities and animal feeding operations to extract and recover phosphorus from biosolids and manure. The remaining biosolids or manure, which contain crop-friendly ratios of nitrogen-to-phosphorus, can be land-applied, thus minimizing the amount of waste trucked to disposal sites, and reducing or even eliminating the incidence of nutrient pollution from soil runoff. In addition, municipalities and farms can sell the recovered phosphorus on the open market, and engage in the trading or marketing of nutrient credits.