By Dr. Karl Wyant, Director of Agronomy at Nutrien

Opportunity for Industry Action

Phosphorus sustainability has several key challenges, both on the mining and manufacturing front and extending through to the grower. On the mining side, key initiatives for sustainability will need to become more widely accepted. These practices include reducing the overall environmental footprint of the extracted materials and ramping up the waste management and reclamation sides on the back end. On the farming side, some growers have abundant access to phosphate fertilizers, and some are missed along the supply chain for one reason or another. A key challenge for the fertilizer retailers will be increasing access of phosphorus to those who need it most to drive sustainable intensification while leveraging legacy phosphate and advanced application technologies (4R) to those who are looking to reduce their inputs via soil samples and variable rate application of fertilizers. Another opportunity includes incorporating more recycled materials (e.g., composts and manures) into nutrient management plans and removing barriers that prevent their widespread use (e.g., handling, storage, and transport).

Sustainability at Nutrien

At Nutrien, our purpose is to “Grow our World from the Ground Up”. With 23,500 employees and a global footprint of operations and investments, Nutrien’s crop inputs (e.g., nitrogen, phosphorus, and potassium fertilizers) and agriculture retail services reach major growing regions all over the world and over 500,000 unique on-farm accounts. We are well positioned in the phosphorus supply chain because we can influence both the sustainable production of P (mining side) and the sustainable application of phosphorus fertilizer on the farm (application side).

Nutrien Viewpoint on Phosphorus Fertilizer Production

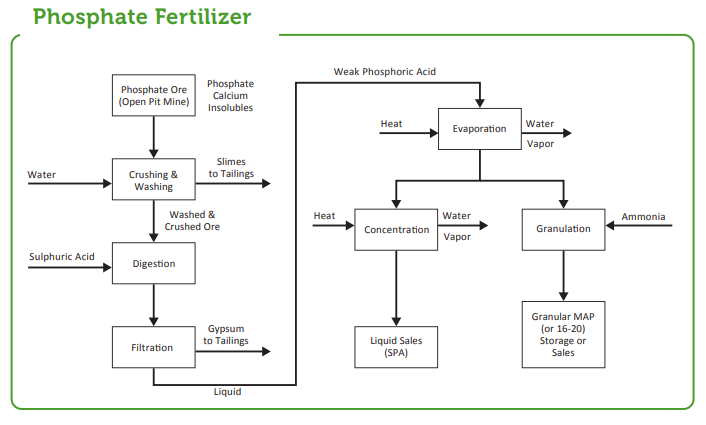

Sustainability is a core part of Nutrien and is evident across our supply chain. On the mining side, we have challenged the phosphorus fertilizer production status quo with targeted sustainability initiatives (Figure 1). Nutrien’s Aurora, NC phosphate operation has pioneered a land reclamation process that has earned state and national awards over the years. We reclaimed 130 acres in 2021 and 390 acres in 2020 and, during this time, we planted approximately 144,000 trees. At our White Springs, FL phosphate mine, we reclaimed 550 acres in 2021, adding to the nearly 1,680 acres reclaimed in 2020 and 2019. Over the three-year period, we also planted approximately 981,000 trees. As White Springs’ operations have expanded, the site’s environment team has been working alongside state officials in relocating gopher tortoises to a protected on-site location – a reclaimed phosphate mine that is ideally suited to their habitat preferences. In another example, we are currently working to incorporate cleaner ammonia sources into our fertilizer production lines, resulting in a decreased environmental footprint for popular fertilizers like phosphorus acid and monoammonium phosphate. At the end of the day, our sustainable production and manufacturing practices are carried on through to the next step when applied to the farm field (e.g., application).

Figure 1 – Phosphorus fertilizer manufacturing has many opportunities to drive sustainability outcomes (Nutrien 2022 Fact Book.pdf).

Nutrien Viewpoint on Phosphorus Fertilizer Application

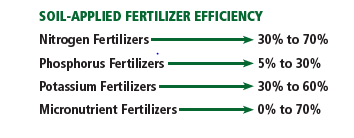

On the farm, phosphorus is required in large quantities by the crop to produce a high quality yield. To meet this demand, growers often turn to phosphorus fertilizers in either liquid or dry form. In a perfect world, 100% of the phosphorus fertilizer application would be used by the crop to produce yield and fertilizer losses would be minimized. However, as Figure 2 shows, use efficiency of fertilizers vary greatly by nutrient category. Phosphorus is especially prone to crop use inefficiencies due to its reactive nature in the soil and its tendency to “tie up” with other elements before the crop can use it.

Figure 2 – Estimates of soil applied fertilizer efficiencies (amount used by crop relative to how much was applied total to the soil), (Fixen et al. 2014).

Nutrien uses advanced agronomy training and data sources to help optimize phosphorus fertilizer efficiency across the globe. Additionally, Nutrien is a strong proponent of the 4R principles to help optimize plant uptake and reduce the risk of environmental externalities (e.g., runoff, eutrophication of waterways) (Figure 3) from occurring. Our teams receive extensive training on the 4R principles to help promote sound fertilizer stewardship under field conditions. Examples of training including fertilizer placement (banding vs. broadcast) and soil pH management and amendment use to help prevent tie up under acidic and alkaline conditions.

Figure 3 – 4R Nutrient Stewardship provides a framework to achieve fertilizer management goals and improve sustainability (What are the 4Rs | Nutrient Stewardship).

Properly managed fertilizers support cropping systems that provide economic, social and environmental benefits. Thus, responsible fertilizer management is a key sustainability practice.

Thank you for the opportunity to join the Sustainable Phosphorus Alliance. We are looking forward to the dialogue with key stakeholders from the different groups that are represented. Together, we can work to achieve a more sustainable phosphorus future for all. Please check out the links below or contact me to discuss phosphorus sustainability in more detail.

Opinions expressed here do not necessarily reflect those of the Sustainable Phosphorus Alliance.

Dr. Karl Wyant serves as the Director of Agronomy at Nutrien. Please visit nutrien-ekonomics.com and smartnitrogen.com for the latest in nutrient management topics and other free resources.